Hyland Concrete Technical Bulletin – Pouring ready mix in hot weather

Hot Weather Concreting Considerations for Standard Concrete Applications

What is considered hot weather?

As per CSA A23.1-7.1.1 hot weather concreting occurs when the ambient air temperature is at or above 27 °C, or when there is a probability of the temperature rising above to 27 °C during the placing period (as forecast by the nearest official meteorological office); additionally, low relative humidity conditions, high wind speeds, solar radiation or heat gain are other climatic factors that will trigger hot weather curing conditions.

Why to consider when pouring ready mix in hot weather ?

These conditions can result in the following challenges for the concrete contractor:

- Increased concrete water demand

- Accelerated concrete slump loss

- Increased rate of setting leading to placing and finishing difficulties

- Increased tendency for plastic shrinkage cracking

- Increased concrete temperature resulting in lower ultimate strength

- Increased potential for thermal cracking/li>

What are the maximum allowable temperatures?

MTO and projects following the British Columbia Provincial Standards: As per CSA A23.1-7.1.1, the concrete temperature at the time of discharge from the truck shall be at or between 10 and 28 °C, with the exception of HPC and silica fume overlays, which shall be at or between 10 and 25 °C; additionally, when the air temperature exceeds 28 °C and the concrete temperature exceeds 25 °C, the concrete shall be discharged within 1 hour after the introduction of the mixing water.

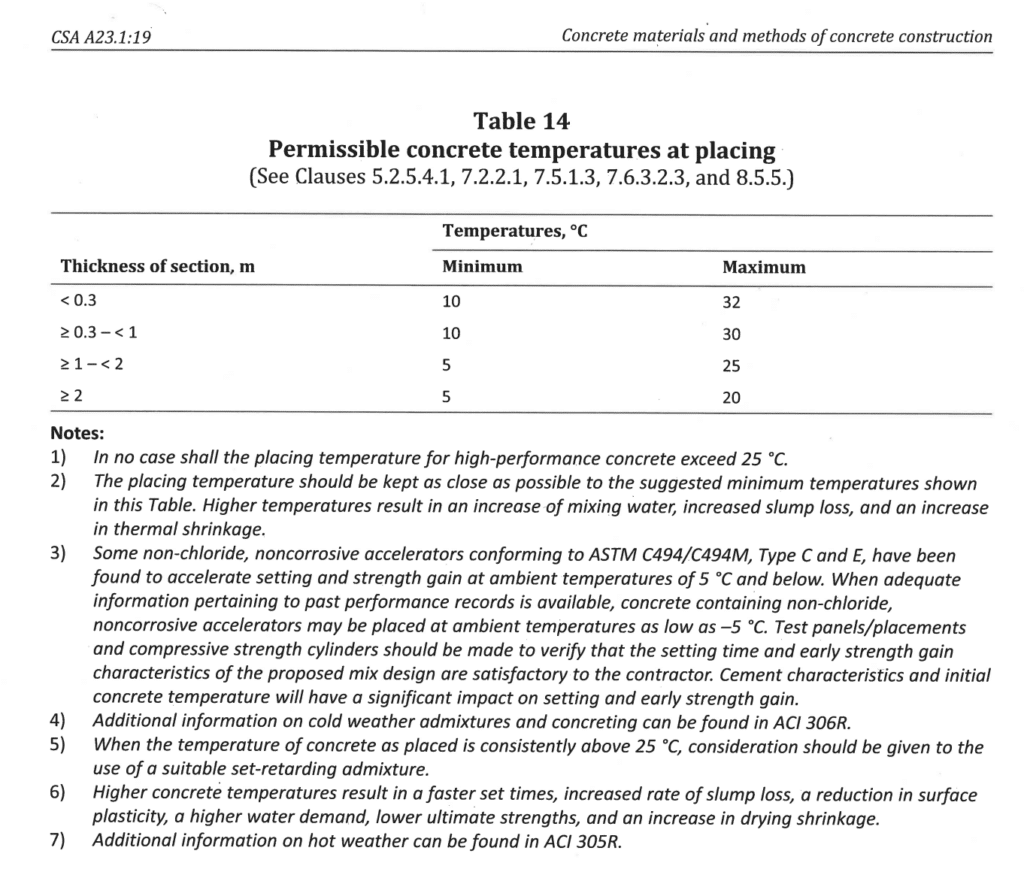

CSA based projects and specifications: CSA A23.1-8.5.5 states that the maximum concrete temperature at delivery shall be specified when the owner requires a delivery temperature lower than the values given in Table 14.

How to plan to minimize the effects of hot weather?

Depending on the application and type of finish some of the recommended protective measures include:

- Consider ordering super plasticizers and a slump to allow for rapid placement.

- Consider the use of supplementary cementing materials or retarding admixtures, as this could affect the finishing of flatwork applications.

- Consider the use of supplementary cementing materials or retarding admixtures, as this could affect the finishing of flatwork applications.

- Be ready to receive and place concrete, consider scheduling pours to start early in the morning or later in the afternoon and have sufficient manpower to manage the placement, finishing and curing process.

“During hot weather be prepared and plan to pour early in the day.”

During the hot weather season when peak ambient temperatures exceed 25 °C around the placing period, ice cooling might be required deliver concrete below the specified maximum concrete temperatures of your project, this process requires additional setup costs and considerations.

Please contact your Hyland Precast Inc. Concrete Sales Representative for more information.

Resource links pouring ready mix in hot weather

CSA

Hyland Ready Mix Concrete FAQ